"Arch Duke Maxyenko, Shit Talk Extraordinaire" (arch-duke-maxyenko)

"Arch Duke Maxyenko, Shit Talk Extraordinaire" (arch-duke-maxyenko)

04/16/2020 at 13:54 • Filed to: None

1

1

12

12

"Arch Duke Maxyenko, Shit Talk Extraordinaire" (arch-duke-maxyenko)

"Arch Duke Maxyenko, Shit Talk Extraordinaire" (arch-duke-maxyenko)

04/16/2020 at 13:54 • Filed to: None |  1 1

|  12 12 |

RamblinRover Luxury-Yacht

> Arch Duke Maxyenko, Shit Talk Extraordinaire

RamblinRover Luxury-Yacht

> Arch Duke Maxyenko, Shit Talk Extraordinaire

04/16/2020 at 14:03 |

|

And now for something completely different the same. A man with three buttocks.

What’s interesting about doing a details-exact cover is that it’s like a studio documentary bit that never was - showing all the parts in the stew.

Rusty Vandura - www.tinyurl.com/keepoppo

> Arch Duke Maxyenko, Shit Talk Extraordinaire

Rusty Vandura - www.tinyurl.com/keepoppo

> Arch Duke Maxyenko, Shit Talk Extraordinaire

04/16/2020 at 14:19 |

|

The new Robert plant album, carry fire or hang fire or whatever it was, that title track caused me to develop a whole new respect for Robert plant and a new appreciation for the music of led Zeppelin.

Rusty Vandura - www.tinyurl.com/keepoppo

> RamblinRover Luxury-Yacht

Rusty Vandura - www.tinyurl.com/keepoppo

> RamblinRover Luxury-Yacht

04/16/2020 at 14:21 |

|

Dude! I was thinking about that exact Monty Python thing myself just in the last couple of days.

also, we need to brainstorm how to engineer the embouchure mechanism

for the trombone rifle.

Highlander-Datsuns are Forever

> Arch Duke Maxyenko, Shit Talk Extraordinaire

Highlander-Datsuns are Forever

> Arch Duke Maxyenko, Shit Talk Extraordinaire

04/16/2020 at 14:43 |

|

That is m y favorite led zepplin album of all time.

RamblinRover Luxury-Yacht

> Rusty Vandura - www.tinyurl.com/keepoppo

RamblinRover Luxury-Yacht

> Rusty Vandura - www.tinyurl.com/keepoppo

04/16/2020 at 15:05 |

|

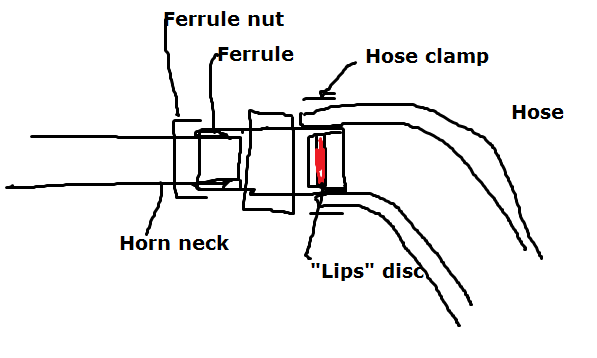

I would handle the embouchure by putting a double compression fitting onto the horn section, removing the ferrule and nut from one side, inserting a rubber disc cut from scrap with a slit cut in it into the ferrule cavity, and linking it to whatever with flex. As this:

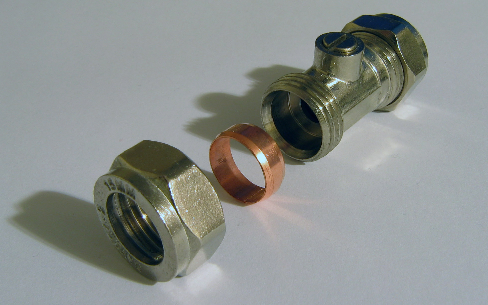

Compression fitting somewhat as below:

Rusty Vandura - www.tinyurl.com/keepoppo

> RamblinRover Luxury-Yacht

Rusty Vandura - www.tinyurl.com/keepoppo

> RamblinRover Luxury-Yacht

04/16/2020 at 15:41 |

|

I could not have conjured up that idea myself. Rigidity of the rubber or neoprene, size of the opening, and the amount of pressure would all be variables. I guess first, I should find a sacrificial horn.

RamblinRover Luxury-Yacht

> Rusty Vandura - www.tinyurl.com/keepoppo

RamblinRover Luxury-Yacht

> Rusty Vandura - www.tinyurl.com/keepoppo

04/16/2020 at 16:47 |

|

The size of various pieces would be dictated partly by the horn, and partly by the connection to the valve from the spray tank kit. You might end up with a “conversion” style compression coupling with a 3/8" tubing connection on one side and 5/8" on the other, or some such.

You might for testing purposes buy a cheap plastic vuvuzela until such time as you can source a suitable horn.

The rubber washer, I admit I don’t know an ideal thickness. My instinct would be to cut a scrap of ~1/8" rubber from something

and then progressively widen the slot to see what works best as a reed. I’d suggest radiator hose except that it’s fiber-reinforced and so rigid I don’t think it would “flap”. Red antimony

rubber like a toilet plunger or piece of gasket is probably about right.

In fairness, you might be able to blow-test a rubber disk with your own mouth to try some different sizes and designs of reed, though your mouth pressure would be lower than the tank and you might not have enough. Given that the spray tank drives a lot of the design (tubing, reed sizes, musket choice, musket stock modification, backpack mounting)

and is also conveniently pretty

cheap and would allow reed development

, it might be the first step.

RamblinRover Luxury-Yacht

> Rusty Vandura - www.tinyurl.com/keepoppo

RamblinRover Luxury-Yacht

> Rusty Vandura - www.tinyurl.com/keepoppo

04/16/2020 at 16:51 |

|

I should note - my place of work has most of the things that this would require. If I find myself subject to being bored out of my mind here at work sometime soon, I might be able to do a reed size and materials test. No promise, but neither is it impossible.

Rusty Vandura - www.tinyurl.com/keepoppo

> RamblinRover Luxury-Yacht

Rusty Vandura - www.tinyurl.com/keepoppo

> RamblinRover Luxury-Yacht

04/16/2020 at 18:31 |

|

Rubber disc. Are you thinking like innertube rubber?

Rusty Vandura - www.tinyurl.com/keepoppo

> RamblinRover Luxury-Yacht

Rusty Vandura - www.tinyurl.com/keepoppo

> RamblinRover Luxury-Yacht

04/16/2020 at 18:43 |

|

I’d like to try and take you up on that. First, I need to find a garage sale trombone.

RamblinRover Luxury-Yacht

> Rusty Vandura - www.tinyurl.com/keepoppo

RamblinRover Luxury-Yacht

> Rusty Vandura - www.tinyurl.com/keepoppo

04/16/2020 at 18:46 |

|

Might be too thin and flimsy

for a reed, might not, at least if of the bicycle kind

. My concern would be being able to keep it in place - it’s not very stiff, so the disc idea like I described might not

work exactly. A piece stretched over the end of the tube (not stretched very tightly) might still work, it would just be more involved.

I’m almost certain I remember something about an inner tube rubber noise maker in a 50's craft book back at the house, though I don’t remember details.

A tire patch of the disc kind might work, cut down.

RamblinRover Luxury-Yacht

> Rusty Vandura - www.tinyurl.com/keepoppo

RamblinRover Luxury-Yacht

> Rusty Vandura - www.tinyurl.com/keepoppo

04/16/2020 at 19:15 |

|

I am by no means an expert on making musical instrument guns out of chemical sprayers and hardware store junk, but I may be the closest we’ve got.